Full control and characterization tools.

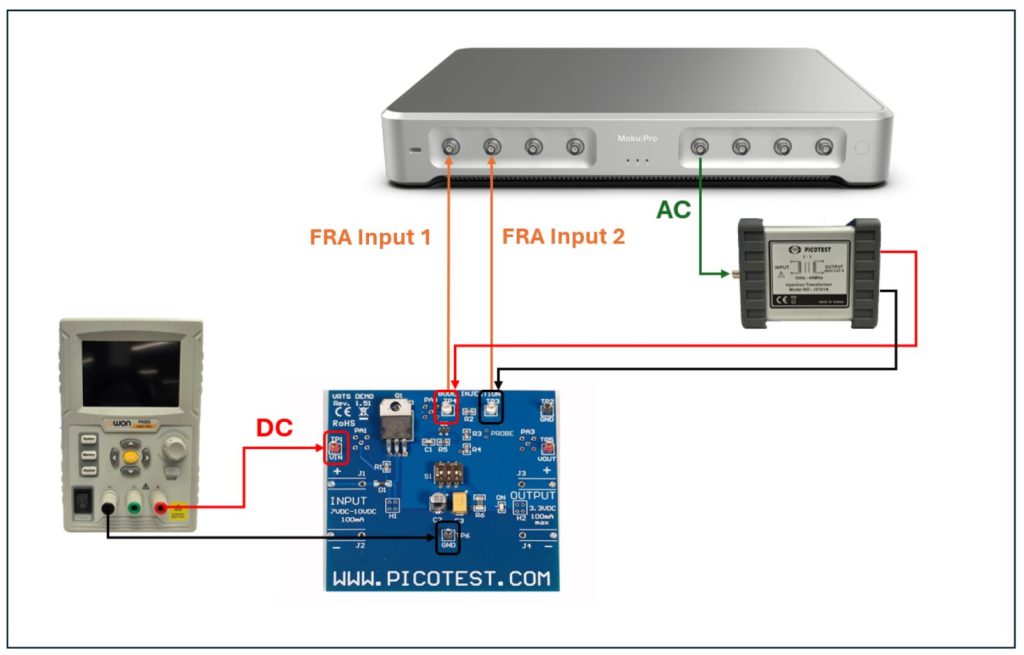

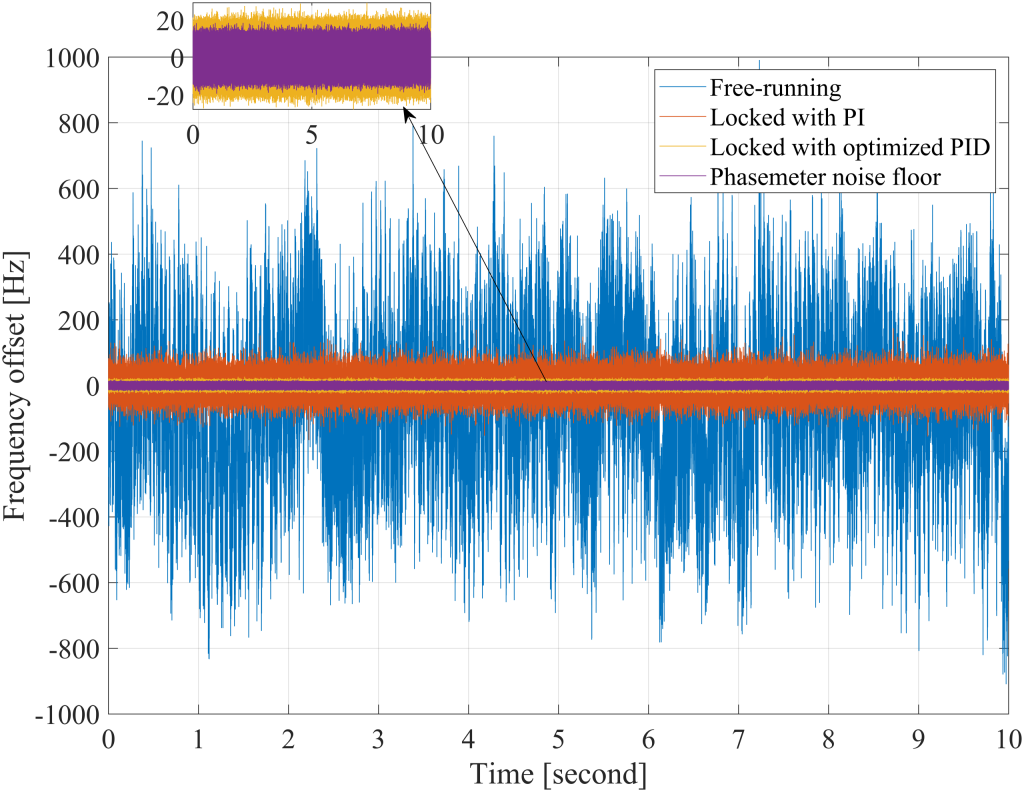

Moku offers a complete, closed-loop control system in a single device, eliminating the need for multiple standalone instruments. With integrated instruments like the PID Controller, Oscilloscope, Data Logger, and Frequency Response Analyzer, you can monitor, control, and characterize your system with ease. Use the Frequency Response Analyzer to perform Bode analysis and measure transfer functions of electrical, mechanical, or optical systems — making Moku ideal for optimizing feedback loops, identifying resonances, designing filters, and determining bandwidth.