After I graduated with my engineering degree, I worked as an engineering lecturer. Lecturing wasn’t actually my forte, though; I was always most concerned with making my course’s project-work work.

We all end our engineering degrees with a capstone or senior design project. It should be the time when we can take both the concrete learnings and abstract conceptualizations from our courses and consolidate that knowledge. In the language of Kolb’s Experiential Learning Theory, these projects allow us to engage in active experimentation by applying previous experiences to new situations, learning how effectively they can be applied, and determining what changes need to be made. It’s this that, more than anything else, builds an engineer’s intuition and prepares them to succeed in the workforce after earning their degree.

But how can you scaffold projects that allow students to find the limits of their knowledge, rather than the limits of their equipment? At first, I ordered palettes full of electronic components, development kits, cables, bearings, wheels, and anything else I thought a student could possibly need to complete the projects I had set (Figure 1). I was trying to make sure they had the ability to build their solutions, not be biased toward my own solution.

Figure 1: Before starting any project, my students were given access to hundreds of Arduinos, sensors, and mechanical and electrical components to give as wide a solution space as possible.

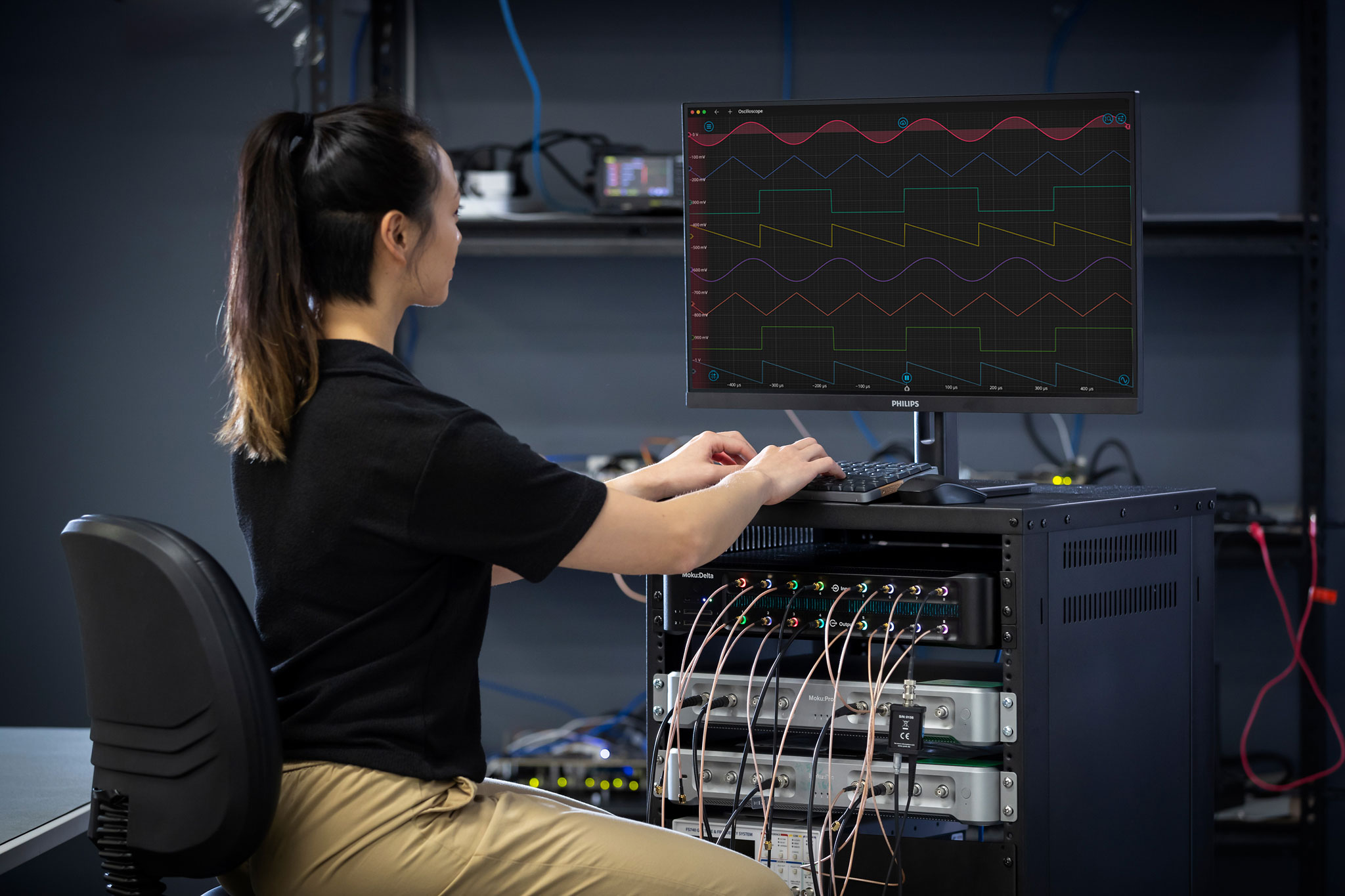

One thing I couldn’t solve until I started at Liquid Instruments was removing the restrictions around the development, test, and validation of solutions. Test and Measurement equipment!

Sure, the students had access to Oscilloscopes and Waveform Generators, and sometimes they could build passable PID Controllers and things out of Arduino boards – what else is there, I thought?

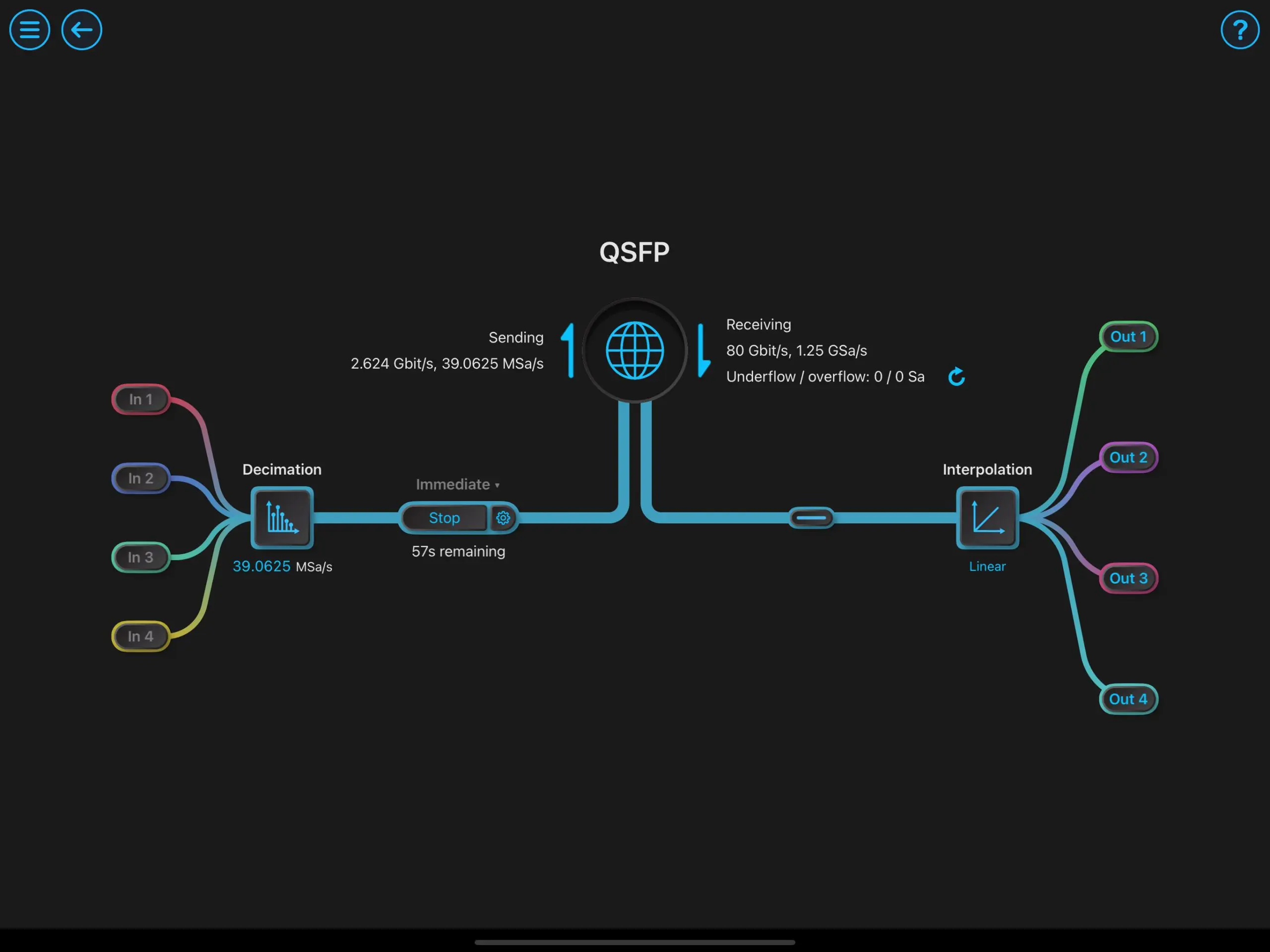

Enter Moku:Go. This next-generation device offers more than FPGA-based, software-defined instruments to deliver maximum performance flexibility. It’s extremely affordable and means that students have access to the right tool for the job, whatever the job might be. Here’s some inspiration for how students around the world are using Moku:Go for genuine active experimentation:

- Using the Data Logger with the Arbitrary Waveform Generator allows students to record real-world stimuli, then play them back in to their designs over and over. By validating the real design with real signals (rather than one or both being simulated), the students learn that the real world is messy, but they also learn how to overcome that messiness!

- Building simple LiDAR and Ultrasonic ranging systems for process control and measurement. They see for themselves: Multi-path effects are real, pervasive, and can be difficult to deal with.

- Embedded computer vision like blob tracking is neat, but when you use the Moku:Go PID Controller to integrate that in to a feedback control system, you start to understand processing latency and detection probability in a much deeper way. If you don’t, your system loses stability and throws a ball across the room.

- MATLAB and Simulink are astoundingly powerful and rightly have a core place in engineering education, but Moku:Go and Moku Cloud Compile (MCC) can take your DSP algorithms from Simulink to the real world. For example, adaptive noise cancellation (ANC) is good on a lecture slide, great in simulation, but really has to be heard to be believed.

When students aren’t restricted by the equipment on their bench, when they’re free to use the right tool for the job, they can experiment widely and freely. This experimentation is the core of a capstone project. To make your capstone work, do you need to re-examine your students’ test bench?

Discover the difference that Moku:Go can make for your students today. To learn more or to schedule a demo, contact us at info@liquidinstruments.com.