As electronic devices become smaller, faster, and more complex, ensuring quality through efficient testing has never been more important.

Automated test equipment (ATE) plays a critical role in this process, helping manufacturers quickly verify performance, reduce production time, and maintain reliability across large volumes.

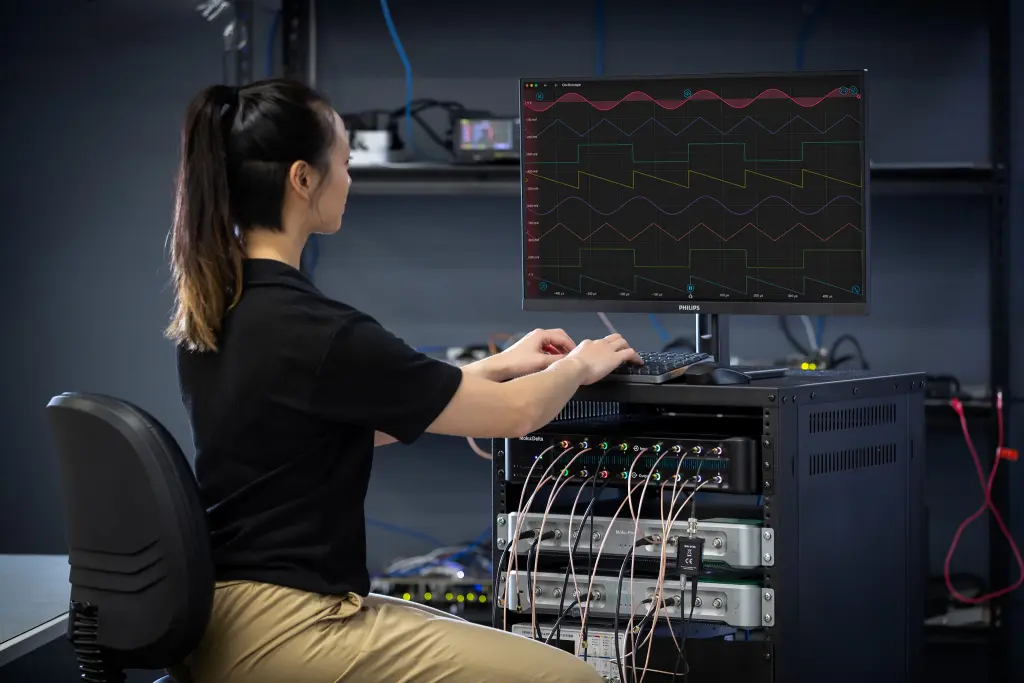

Figure 1: Rack of test equipment in a lab for electronics test.

For any organization involved in electronics manufacturing, properly outfitting the ATE system can dramatically impact throughput, yield, and cost. This guide explores what ATE is, how it benefits modern production, and what to consider when selecting and integrating it into your test procedures.

What is automated test equipment (ATE)?

Automated Test Equipment (ATE) refers to a combination of hardware and software systems designed to automatically test and evaluate electronic devices to ensure they meet performance and quality standards. Instead of manually connecting instruments and running measurements, ATE systems apply signals, capture responses, and compare results against predefined specifications.

These systems are essential in electronics manufacturing, semiconductor testing, and aerospace and defense applications, where speed, precision, and repeatability are critical to maintaining product reliability and production efficiency.

Benefits of automated test equipment

- Reduced test cycle time: Automation allows parallel or high-speed testing of multiple devices simultaneously.

- Higher accuracy and repeatability. ATE minimizes human error, ensuring consistent test conditions.

- Improved yield tracking: Automated data collection enables better analysis of failures and process improvement.

- Scalability. Systems can easily expand or be reprogrammed to test new product lines.

- Cost efficiency. While ATE requires upfront investment, it reduces long-term labor and defect costs.

Key considerations when building an ATE System

Selecting the right automated test equipment depends on both your product type and production goals.

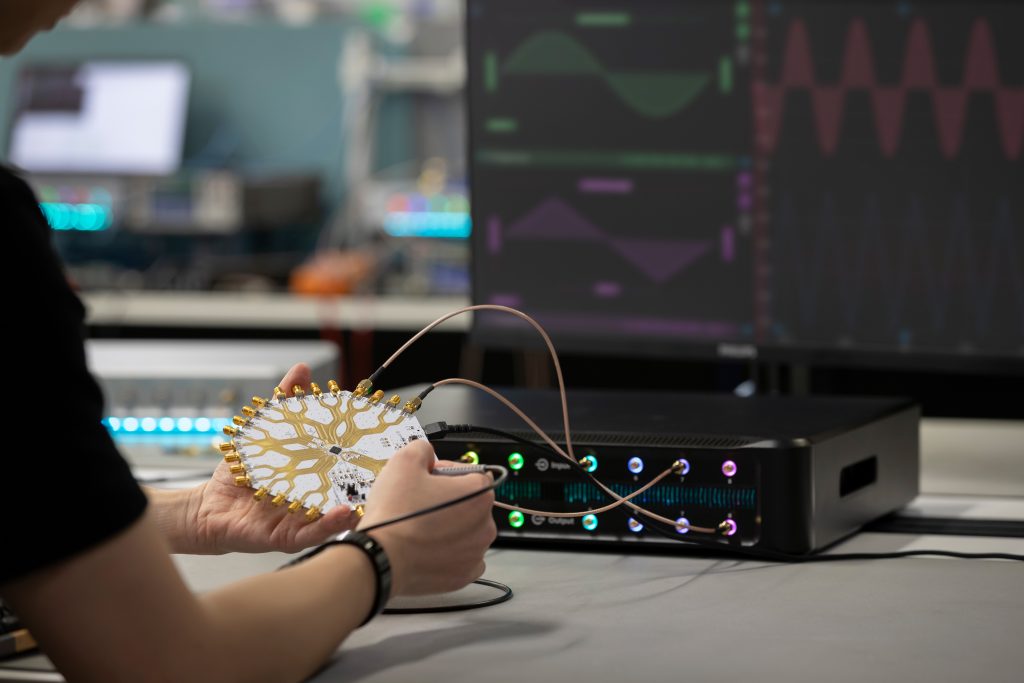

Figure 2: Device under test connected to both stimulus (waveform generator) and analysis to measure response (oscilloscope)

Here are key factors to evaluate:

- Define your device under test (DUT)

Determine what kinds of devices you’ll be testing (analog, digital, or mixed-signal) and the performance parameters that matter most. This will drive your signal range, speed, and accuracy requirements. - Hardware architecture

Look for modular or reconfigurable ATE systems that can evolve with your production. By using a system that is reconfigurable through software, you enable far more flexible scaling than with traditional test equipment, even PXIe-based systems. Scalable platforms allow you to test multiple products without replacing hardware, while supporting different signal types and channel counts. - Test software integration

Software is the backbone of automation. Choose a system that offers intuitive test program development tools and support for common automation languages (Python, LabVIEW, etc.). - Cost and ROI

Balance upfront investment against long-term benefits. A well-chosen ATE system can reduce test time, improve yield, and cut production rework. - Space and scalability

Consider footprint constraints, especially for high-density production lines. Compact, multi-instrument ATE setups can consolidate multiple benchtop instruments into one platform. - Support and maintenance

A reliable vendor should offer calibration, firmware updates, and application support to ensure consistent performance over time.

Applications & use cases for ATE

ATE systems are used across virtually every electronics manufacturing sector, but notable in general electronics design and manufacturing, semiconductor IC test, and aerospace and defense research.

Automated test equipment (ATE) for electronics testing

With growing demand for wireless and IoT devices, ATE platforms must now combine analog, digital, and RF testing capabilities into unified systems. ATE systems also automate verification at both the component and assembly level. They apply precise input signals and analyze output responses to confirm that devices meet specifications.

Modern ATE setups for electronics testing combine signal generators, oscilloscopes, power supplies, and digital I/O in a unified platform controlled by software for full test automation.

Use cases include:

- Testing PCB assemblies for continuity, voltage levels, and logic performance

- Measuring power consumption and signal integrity

- Automating regression tests for consumer or industrial electronics

By automating these processes, manufacturers gain higher throughput and traceable test data while minimizing human error and downtime.

Figure 3: PCBA under test using a Frequency Response Analyzer and Moku:Delta

Automated test equipment (ATE) for semiconductor test

Semiconductor devices demand extremely precise and high-speed testing. Semiconductor ATE systems are designed to validate chips at wafer, package, or final test stages. These systems handle wafer-level and packaged IC testing with high-speed, parallel setups to verify logic, analog performance, and power consumption.

These setups typically feature high channel density to test multiple devices in parallel, and mixed-signal capability to evaluate both digital logic and analog performance.

ATE systems for semiconductors are key to ensuring each integrated circuit performs reliably before it’s assembled into larger systems.

As chips become more complex incorporating analog, digital, RF, and even photonics, ATE systems must offer flexible, software-defined instrumentation to keep pace with rapid design cycles.

Automated test equipment (ATE) for aerospace and defense

In mission-critical applications, ATE provides traceable, repeatable verification, ensuring reliability and safety under extreme conditions. These systems perform rigorous functional and environmental tests on avionics, radar, communication modules, and more to verify performance.

Key features often include:

- High reliability and precision under vibration, temperature, and EMI stress

- Multi-domain testing (RF, analog, and digital) for complex signal chains

- Long-term data logging and traceability for compliance with standards

Automated test equipment helps defense contractors and aerospace manufacturers meet stringent certification and lifecycle requirements while reducing downtime during maintenance and system upgrades.

Conclusion

Automated Test Equipment (ATE) is the cornerstone of efficient, reliable electronics manufacturing. By understanding your production needs and selecting a scalable, software-driven ATE system, you can improve test throughput, lower costs, and enhance product quality.

Whether you’re testing semiconductor devices, , or complex mixed-signal systems, modern ATE offers a path to smarter, more connected manufacturing.