Optical frequency combs (OFCs) have become an essential tool for precisely measuring frequency and distance, making them useful for applications such as LiDAR, 3D surface profilometry of micro/nano devices, and gravitational wave detection. A typical OFC measurement involves many time-of-flight measurements, which determine the distance to an object or surface by the time taken for a pulse of laser light to reflect off the object and return to the detector, usually an optical interferometer. While the measurement is conceptually simple, it can be incredibly challenging to perform both precisely and quickly, usually sacrificing one for the other.

Recently, researchers from the Xi’an Institute of Optics and Precision Mechanics (XIOPM) and Huazhong University of Science and Technology (HUST) in China have developed a novel method for precision distance measurement, using two optical frequency combs for an optimal balance of precision and speed. To assist with their research, the scientists are using Moku:Lab, an FPGA-based device that delivers a reconfigurable suite of test and measurement instruments. Leveraging the Moku Laser Lock Box as a streamlined, all-in-one laser locking solution, the team has significantly improved the quality of their measurements as a result. Their results are now available from the Advanced Photonics Nexus.

The challenge

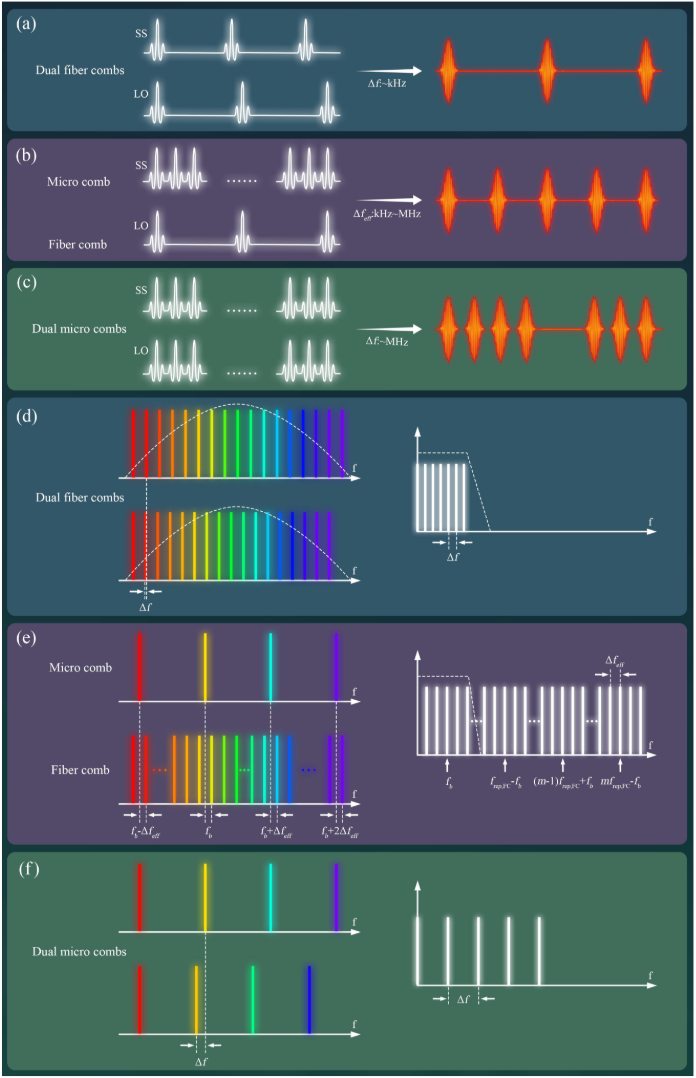

Several factors limit the precision of distance calculations, including laser frequency stability and the time resolution of the measurement setup. One tool in particular that has helped address these problems is the optical frequency comb, which generates ultrashort (femtosecond) pulses of light at an incredibly stable repetition rate. As seen in Figure 1, the repetition rate is a critical parameter of the OFC which determines its spectral resolution — the spacing of its “teeth” in the frequency domain.

Two OFCs are often used in conjunction through a technique called dual-comb ranging. By using an OFC with a slightly different repetition rate as the local oscillator (LO), the spectral resolution can be decreased to Δf, the difference in the repetition rates (Figure 1d). While the stability of dual-OFC systems is certainly useful for precision ranging, the repetition rate is low, meaning that pulses are sent out with large time gaps in between them (Figure 1a). This limits the rate at which the LiDAR system information can calculate information about the target, commonly called the update rate.

Figure 1: The interferometry characteristics of different types of dual comb sources. Fiber combs and micro combs both have distinct advantages and disadvantages. Reprinted from [1].

One potential solution to this issue lies in the use of a micro-ring resonator, or Kerr frequency comb, as an OFC. The research team from XIOPM and HUST in China have developed a dual-frequency comb (DFC) method that combines the best aspects of both a traditional OFC and a micro-ring resonator (MRR), maintaining a high precision while increasing the update rate substantially.

The solution

Micro-ring resonators are typically small structures patterned onto a substrate, and generate a frequency comb output when driven with a pump laser. While the repetition rates of MRRs can be incredibly high (Figure 1b), they suffer from repetition rate fluctuation and optical frequency instability, which limit the long-term ranging precision.

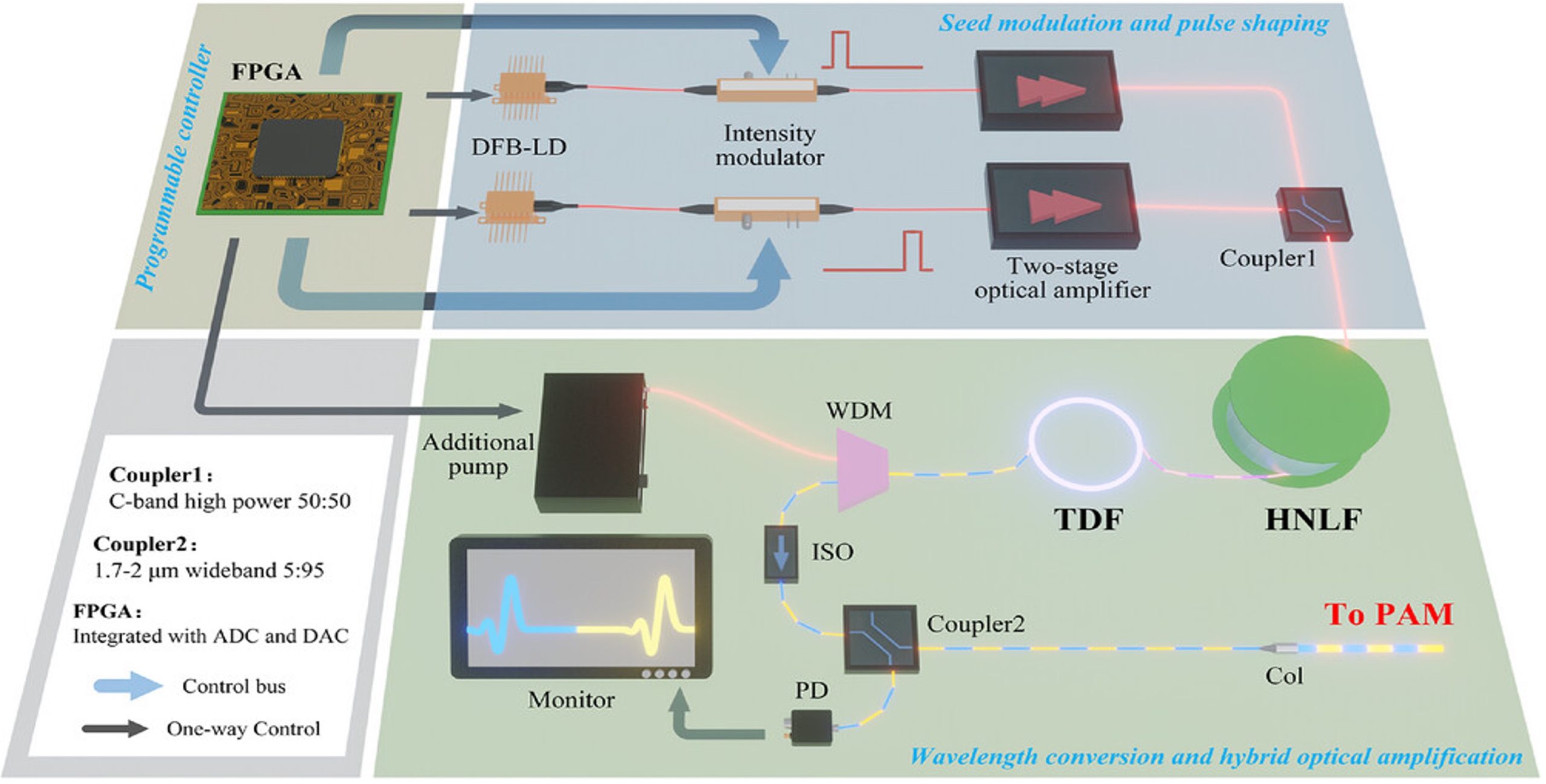

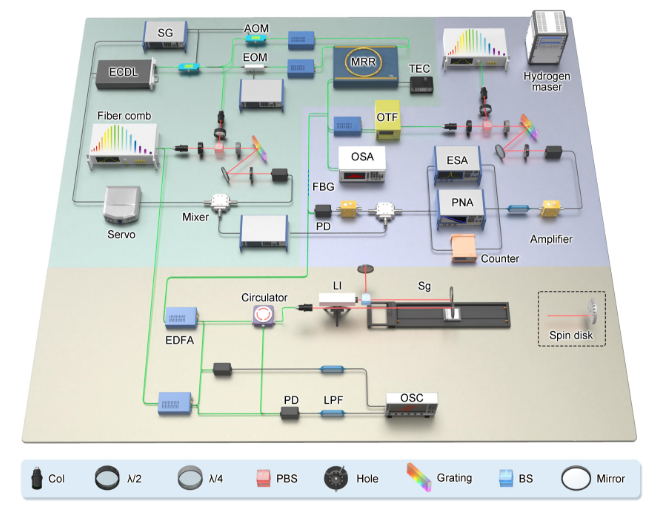

The solution proposed by the research team at XIOPM and HUST was to use a DFC setup with one fiber comb and one MRR, as seen in Figure 2. In this setup, a modulated diode laser beam (ECDL) is used as the pump source for the MRR. The output from the MRR is then passed through a fiber amplifier (EDFA) before probing the sample under test. The fiber comb provides both a stable LO source for demodulation, and, critically, provides a reference signal for locking the pump laser. The Moku:Lab Laser Lock Box (labeled as the servo in Figure 2) forms a closed feedback loop, monitoring the error signal between the pump and ultra-stable fiber comb and providing feedback to the laser via the built-in PID Controller, which will adjust and “pull” the pump frequency to the correct value. This way, the researchers are able to precisely and rapidly control the frequency difference between the two sources. The increased stability of the pump laser, in turn, improves the stability of the signal emitted by the MRR.

Zhichuang Wang, a Ph.D. student at XIOPM and one of the primary authors of the paper, says that the Laser Lock Box has greatly helped in their efforts to increase the precision of their DFC setup:

“We’ve tried other servos and the performance was not sufficient. I have been using Moku for about one and a half years. I enjoy the integrated nature of the Laser Lock Box; it requires no external mixers and has an included PID controller.”

Figure 2: Schematic for the DFC ranging experiments at XIOPM. Here, Moku:Lab is depicted as the servo. Reprinted from [1].

The result

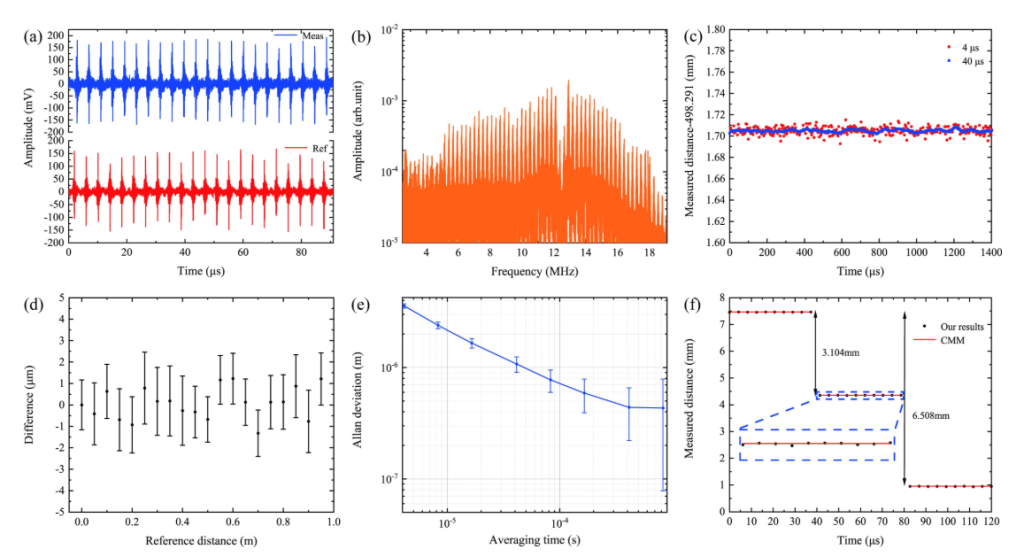

By using a hybrid DFC system, the research team at XIOPM and HUST were able to leverage the high repetition rate of the MRR with the stability of the fiber comb. To benchmark their system, they imaged a rapidly spinning disk with grooves of varying depths. The results can be seen, alongside a commercial coordinate measuring machine (CMM), in Figure 3f.

Figure 3: Measurement results from Ref 1. Key results include (e), the Allan deviation measurements of the DFC setup, and (f), the results of the ranging experiment on the grooved disk. Reprinted from [1].

With the increased stability from the locked pump laser, the team ultimately determined that the precision of their DFC setup could reach 3.572 μm with a 4.136 μs averaging time, and 432 nm with an 827.2 μs averaging time. Due to the large difference between the repetition rates of the MRR and fiber comb, the measurement speed of the system was enhanced by nearly 200x when compared to a dual-fiber-comb system.

The team’s DFC setup is an ultra-stable ranging solution that maintains both high precision and rapid update rates, while featuring dynamic control. A sub-micron LiDAR sensor could have applications in manufacturing and machining, where precision and agility are essential.

Although this particular experiment has been completed, Wang sees the other instruments available for Moku:Lab useful in his future endeavors.

“We are planning on using the Moku Phasemeter for characterization of phase noise, as well as the Time & Frequency Analyzer as a frequency counter for Allan deviation measurements,” he said.

Questions?

Get answers to FAQs in our Knowledge Base

If you have a question about a device feature or instrument function, check out our extensive Knowledge Base to find the answers you’re looking for. You can also quickly see popular articles and refine your search by product or topic.

Join our User Forum to stay connected

Want to request a new feature? Have a support tip to share? From use case examples to new feature announcements and more, the User Forum is your one-stop shop for product updates, as well as connection to Liquid Instruments and our global user community.

References

[1] Z. Wang, J. Zhi, H. Wu, B. E. Little, S. T. Chu, J. Zhang, Z. Lu, C. Shao, W. Wang, and W. Zhang. “Rapid and precise distance measurement with hybrid comb lasers,“ (2024). https://doi.org/10.1117/1.APN.3.4.046006