Neeraj Prakesh, a graduate research assistant at the University of Colorado, Boulder, and his team are working hard to develop new laser sources and expand the development of frequency combs, which are optical spectra consisting of equidistant lines that act like a ruler for light. The researchers have spent years developing laser sources with widely varying wavelengths for different applications, including a novel counterpropagating all-normal dispersion (CANDi) fiber laser[1]. CANDi is a single-cavity, dual-comb laser source that can generate two nearly identical frequency combs in opposite directions, dramatically decreasing the amount of equipment needed to combat unstable timing jitter. This discovery benefits a range of dual-comb applications including imaging, spectroscopy, remote sensing, and light detection and ranging (LiDAR).

Figure 1: Moku:Lab on the optical table

To implement CANDi fiber lasers, Neeraj utilizes the software-defined PID Controller, Waveform Generator, and Lock-in Amplifier instruments enabled by Moku:Lab, alongside other lab equipment such as an optical spectrum analyzer. Since Moku:Lab delivers a full spectrum of software-defined instruments for test and measurement needs in one device, Neeraj and his team can rely on this versatile solution for multiple projects.

Moku:Lab is a reconfigurable hardware platform that combines the digital signal processing power of an FPGA with versatile, low-noise analog inputs and outputs. The software-defined functionality enables Moku:Lab to provide 14+ test instruments. With Multi-Instrument Mode (MiM), users can combine pairs of instruments to run simultaneously with lossless interconnection.

The challenge

When generating frequency combs, maintaining consistent timing between laser pulses is essential. Slight variations in laser pulse timing can introduce problematic jitter and timing errors into the system. In dual-comb applications such as LiDAR, the lasers must have both high resolution and high speed with little to no noise. Normally, there is a trade-off between these values: achieve high speeds with low resolution, or vice versa.

Neeraj and his team developed CANDi fiber lasers as a new way to combat system noise. With this innovative method, one fiber laser generates two frequency combs in opposite directions. Even in the presence of timing errors and frequency drift, the lasers remain stabilized to one another. This dynamic method has greatly reduced timing errors in the system while reducing the need for extra stabilization electronics.

To implement CANDi, Neeraj and his team needed a waveform generator to produce a reference signal, and a PID controller to lock the timing of the frequency comb’s pulses. They originally used an analog PID controller, but had to experimentally adjust parameters without knowing the frequency response of the controller.

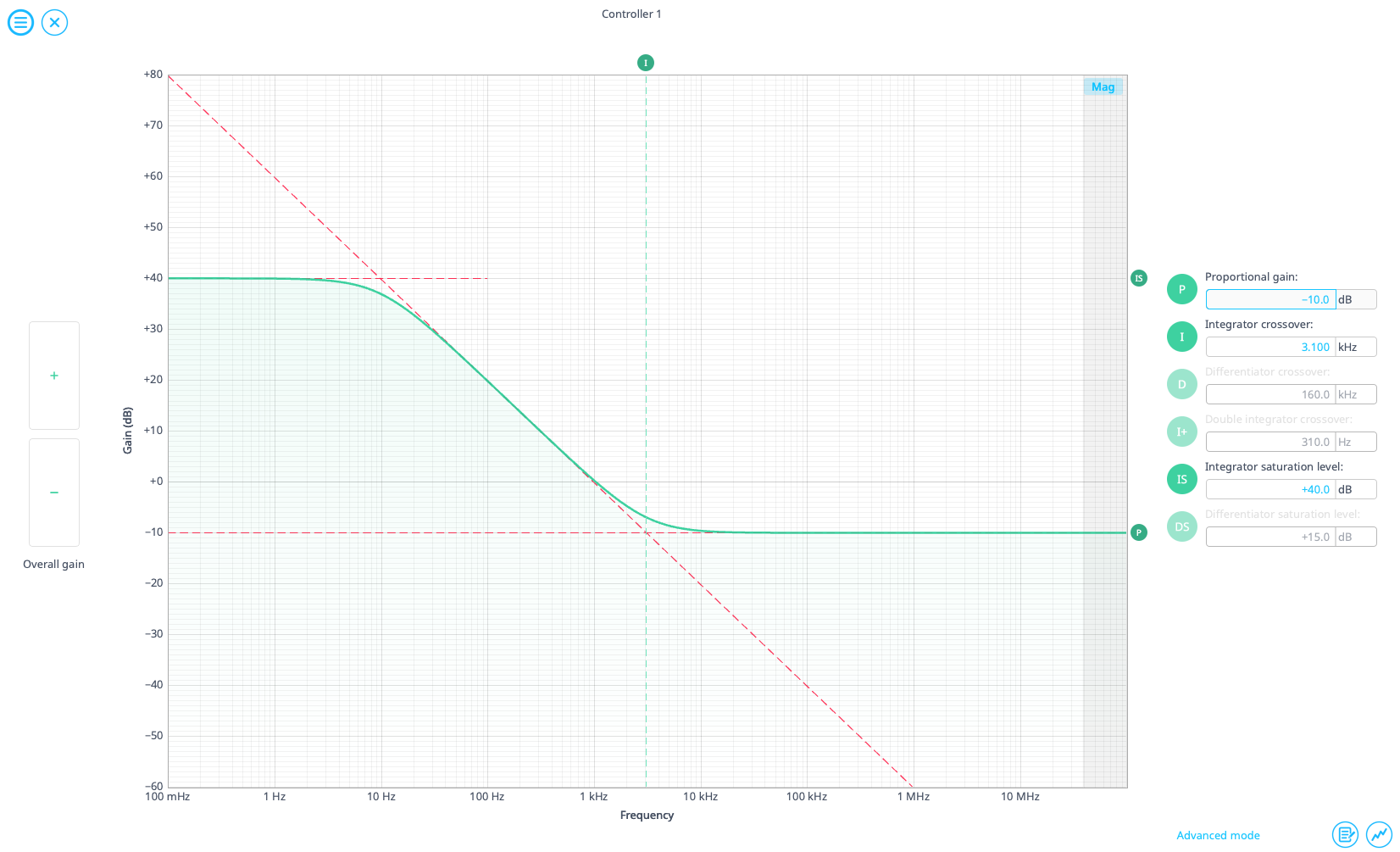

Figure 2: Frequency response graph control of PID gain profile adjustments

When performing signal analysis, Neeraj would manually run each experiment, record the data, export it, and then perform a fast Fourier transform (FFT) to view the results in the frequency domain. This tedious process required precious time, as the team had to repeatedly test the parameters until they identified the ideal gain profiles. But with Moku:Lab, Neeraj can view the frequency response and graphs in real time, vastly accelerating progress.

“Moku gives me real-time frequency domain analysis,” Neeraj said. “That saves a lot of time.”

The solution

With Moku:Lab, Neeraj and his team developed dynamic CANDi, an intelligent way to increase the frame rate in dual-comb applications. This evolution eliminates the trade-off between high speeds and resolutions normally associated with traditional laser sources. By switching to Moku:Lab, Neeraj could leverage the software-defined PID Controller to loosely lock the laser frequencies, minimizing jitter. By replacing analog electronics with Moku:Lab, the team can easily set gain profiles and view the frequency response of their transfer function — all in the Moku app. With this method, they have also eliminated time-consuming guesswork, since they can now tune and adjust parameters, see the system response, and watch the signal change in real time.

The researchers implemented their device in additional experiments as well, especially after realizing that the Moku:Lab Lock-in Amplifier had far better bandwidth than alternate models they considered. In fact, due to the versatility of Moku devices, lab members often find themselves in line to use it for their own research.

“Frankly, Moku:Lab is in great demand in our lab,” Neeraj said. “People are always fighting to use it at any given time — it’s very popular in our group.”

Additionally, since all Moku devices offer Multi-Instrument Mode, the team now can further optimize their setup with the Moku:Lab Waveform Generator, PID Controller, Oscilloscope, and Spectrum Analyzer. Now, with just one piece of equipment, the team can create a reference signal, set gain profiles, and view frequency responses, all in real time.

The result

While increasing the efficiency of his experiments, Neeraj found that Moku:Lab helped optimize the physical setup of his lab as well.

“It saves space,” he said. “You don’t need to have multiple things stacked on top of each other to do these analyses. You can just switch between instruments.”

Moku:Lab will continue to aid Neeraj in his research on dynamic CANDi lasers. Looking ahead, Neeraj will continue using the Moku:Lab PID Controller while his colleagues use other software-defined instruments, such as the Laser Lock Box. He can quickly log data to an SD card using the embedded Data Logger, saving time and effort when capturing his results.

The team plans to continue using Moku:Lab in future projects across applications, including custom FPGA programming. Moku Cloud Compile allows users to code, compile, and deploy bitstreams to the FPGA inside Moku devices to enable custom functionality and build complex signal processing pipelines. After viewing our webinar on using ChatGPT to write custom VHDL, the team’s interest was piqued. They plan to test this functionality in various applications in their lab for years to come, also using Moku:Pro and Moku:Go devices in a wide range of tests.

Neeraj and his colleagues have relied on Moku:Lab to advance some of the most cutting-edge laser sources known today. With the team’s recent development, the high-energy single-cavity dual-comb dynamic CANDi fiber laser, many industries stand to see drastic improvements, such as terahertz imaging for security screenings. Another lab at CU Boulder is experimenting with the laser for Raman spectroscopy, with applications in pharmaceuticals and water quality monitoring[2]. To learn more, dive deeper into microscopy and spectroscopy applications.

Questions?

Get answers to FAQs in our Knowledge Base

If you have a question about a device feature or instrument function, check out our extensive Knowledge Base to find the answers you’re looking for. You can also quickly see popular articles and refine your search by product or topic.

Join our User Forum to stay connected

Want to request a new feature? Have a support tip to share? From use case examples to new feature announcements and more, the User Forum is your one-stop shop for product updates, as well as connection to Liquid Instruments and our global user community.

References

[1] B. Li, N. Prakash and S. W. Huang, “Self-starting and low-noise counter-propagating all-normal-dispersion (CANDi) fiber laser,” 2022 Conference on Lasers and Electro-Optics (CLEO), San Jose, CA, USA, 2022, pp. 1-2.

[2] E. Adams, “Researchers make strides in commercializing simplified dual-comb spectroscopy,” Electrical, Computer & Energy Engineering, https://www.colorado.edu/ecee/2022/08/30/researchers-make-strides-commercializing-simplified-dual-comb-spectroscopy (accessed Aug. 24, 2023).